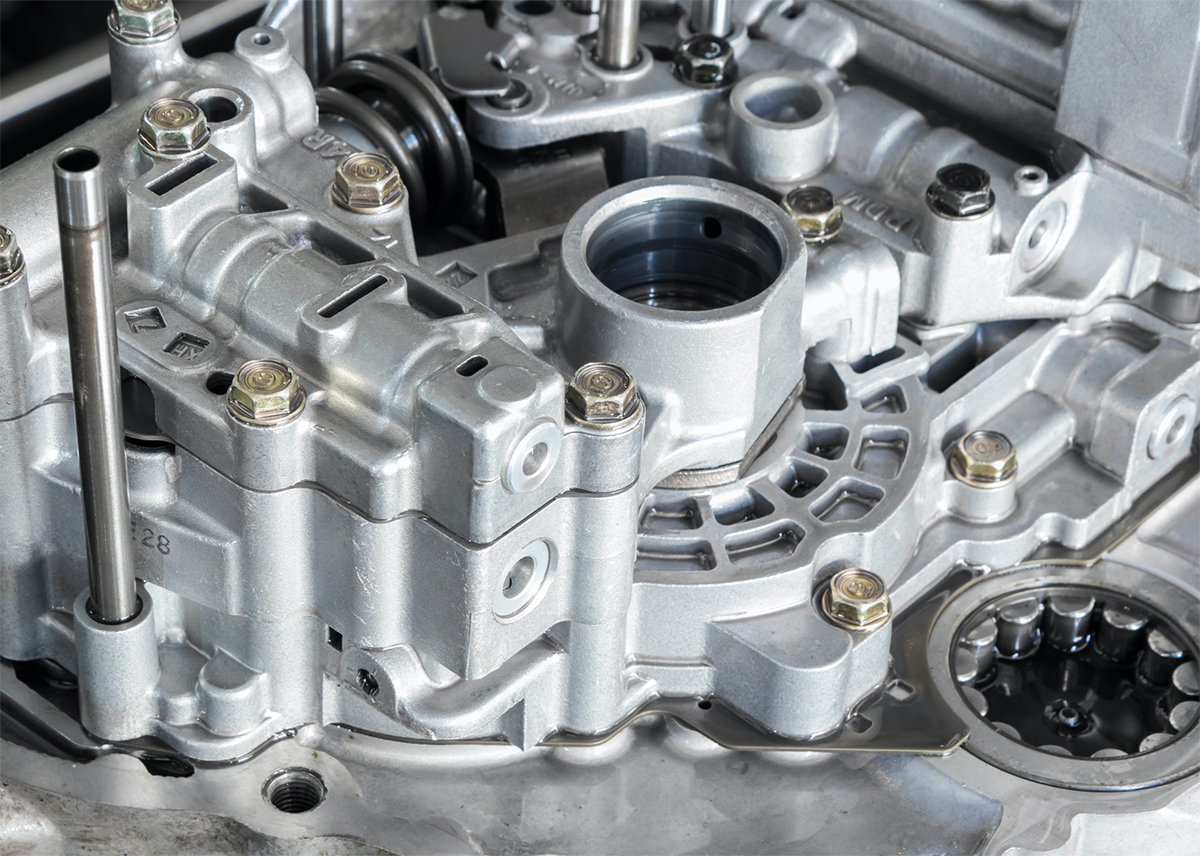

Precision die casting is one of the most efficient ways of accurately manufacturing castings. There are different forms of precision die casting, depending on the metals one is working with. One such method is cold chamber pressure die casting, which is used for metals with a high melting point, such as copper, brass, and aluminum.

This process enables the creation of stronger parts than ones made out of plastic moldings. This enhances the durability and the strength of the equipment that is being made. This process also allows for the production of stronger and denser metal casings, which are generally used for a long time.

Since the furnace is not attached to the machine, this process requires an outside furnace and a ladle to help in pouring the molten metal.

The process of cold chamber pressure die casting.

Cold chamber pressure die casting requires the metal to be heated to a molten state in a furnace not connected to the machine. The liquid is then put into the casting machine and placed in the machine’s chamber. The machine uses a plunge and forcefully pours the liquid metal into a mold. The pressure at which this takes place is usually between 2,000 and 20,000 psi. The separate heating process sets the cold chamber process apart from the hot chamber process.

The molten metal is then transferred to a shot sleeve with the help of the ladle. An injection piston then forces the metal into the die.

This procedure takes place in one go. Thus, it helps in keeping the contact between the injector components and hot metals as short as possible. This also helps increase the life span and efficiency of the machine parts.

This process also allows for the lowering of the melting points of alloys. This process is also ideal for metals with corrosive properties.

Advantages of Cold Chamber Die Casting

- Long-lasting components: Cold chamber die casting helps create strong and long-lasting parts, which improves the visual appeal of the surrounding area.

- Cost-effective process: It is also a highly effective process and saves costs.

- Increased strength: It helps in enhancing the strength of the equipment.

- Easy to assemble: It helps to create fastening elements such as studs and bosses.

- Accurate in dimension: Machine parts can be created with additional heat resistance, stable dimensions, and having a high tolerance level.

The cold chamber process is extremely efficient and makes your equipment stable and visually appealing. It offers a variety of benefits and is the go-to process for working with metals.